GUIDES

FUNDAMENTALS OF

DRILLING & TAPPING

ON SALE NOW

FUNDAMENTALS

OF THREADING ON A LATHE

ON SALE NOW

FUNDAMENTALS OF

WORKING BETWEEN CENTERS

ON SALE NOW

FUNDAMENTALS

OF MILLING

COMING SOON

FUNDAMENTALS

OF SAWING

COMING SOON

METALWORKING

SHOP TERMS

COMING SOON

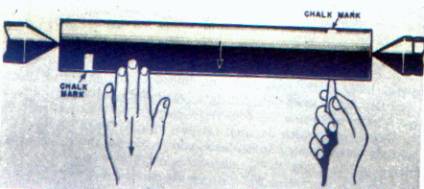

TESTING LOCATION OF CENTERS:

When the centers have been located, test them for

accuracy before drilling and countersinking them. The usual procedure is to

indent them with a center punch deeply enough so that the work can be held

lightly between the lathe centers as shown below. By holding a piece of chalk

stationary against the work (preferably on a rest), and spinning the work as

shown in the illustration, any high spots can be clearly marked at either end of

the piece and determined whether the centers have been located within sufficient

accuracy. Remember that absolute accuracy is not required, nor, in fact, likely

to be attained; but the more accurately located the centers are, the better the

job will be. It is often necessary to change the location of one or both of the

center punch marks before drilling. A satisfactory method of doing so is to hold

the work firmly in a vise, and by means of a center punch held at an angle,

drive the center to be moved in the desired direction.