GUIDES

FUNDAMENTALS OF

DRILLING & TAPPING

ON SALE NOW

FUNDAMENTALS

OF THREADING ON A LATHE

ON SALE NOW

FUNDAMENTALS OF

WORKING BETWEEN CENTERS

ON SALE NOW

FUNDAMENTALS

OF MILLING

COMING SOON

FUNDAMENTALS

OF SAWING

COMING SOON

METALWORKING

SHOP TERMS

COMING SOON

SETTING UP WORK BETWEEN CENTERS

(1)

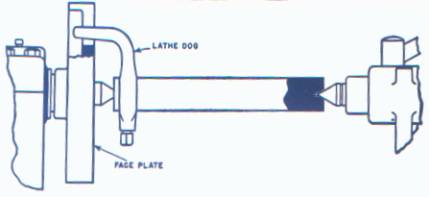

When the lathe centers have been properly inserted in place and approximately

aligned, and the work correctly drilled for mounting, the next step is to mount

the piece in the lathe, usually be means of a faceplate and lathe dog at the

headstock end as shown below.

(1)

The purpose of the lathe dog is to provide a firm connection between the

headstock spindle and the work, and thus drive the work at the same rpm as the

spindle under the strain of cutting. The picture below shows three commonly used

types of lathe dogs. The part of the dog which fits into a slot in the faceplate

is called the tail, which may be either bent, as shown, or straight. Straight

tail lathe dogs are driven by means of a stud attached to and projecting from

the faceplate. The safety lathe dog has a headless setscrew to reduce the danger

of it catching in the operatorís sleeve, which can cause a serious accident.

The clamp lathe dog is used principally for driving rectangular work.

(3) Take particular care if you have a headstock that

has threads to screw on the faceplate that the threads of the headstock spindle

sleeve are clean before screwing the faceplate to them, and avoid damaging them

in any way. The setscrew of the lathe dog should be turned tightly on the work:

if the work is finished, it is good practice to place a split ring of some soft

material such as brass between the setscrew and the work. Make sure the that the

tail of the lathe dog does not bind in the slot of the faceplate.

(4) If you are using a dead center in the tailstock,

it does not revolve with the work as does a live center, it requires

lubrication; a few drops of oil (in the past it was advisable to use white lead

which is no longer available) should be applied to the dead center before the

work is set up, and the tailstock adjusted so that the dead center fits firmly,

but not so firmly as to bind, into the cavity previously countersunk in the

work. It is advisable to apply oil to the dead center at intervals during the

turning operation to reduce wear and prevent damage either to it or to the work.

The heat generated during the turning operation causes the work to elongate

which can cause unnecessary wear on the dead center. Lubrication and pressure

upon the dead center must be checked frequently during the turning operation if

accurate work is to be done without damaging the lathe.